Description

D43 rubber coated magnet with female thread

1. Size: D43*8mm

2. Material: 6pcs of disc neodymium magnet, steel and rubber

3. Color: black, gray, red, orange, white etc.

4. Pulling force: 10-13kgs (standard), higher performance is available to make.

5. Logo: available to add.

6. Package: gift pacakge is available to offer.

7. Application: magnetic mounting for LED lights, camera.

To make pot magnets used in more special conditions, people often need rubber coated on pot magnets, so that rubber coated pot magnets appeared on the magnetic products market and used more and more as a magnetic base or magnetic holder. This rubber coated pot magnet even just called as rubber coated magnets shortly.

The rubber coated pot magnets are assembled with strong neodymium magnets, for bigger size of rubber coated pot magnets are made of several disc neodymium magnets inside (6 pcs of neodymium magnets for D43 & D66 size, 12pcs of neodymium magnets for D88 size ). so that the whole rubber coated magnet is a well-designed magnetic system.

Compared with normal pot magnet, the rubber coated pot magnets have many more advantages:

The bottom surface of rubber coated pot magnet is soft, so it won’t make any damage to other contacted objects;

After rubber coated, it is waterproof, which is better to use in underwater and give the longest working lifetime.

This rubber coated pot magnet usually used for mounting the Modus platform, lighting, cameras, just about anything you can think of putting on a metal surface.

The rubber coated pot magnet also can be screwed with rubber handle that plays a fixing tool in the process of automotive color changing and film and protect the paint from external damage. Equipped with a handle, the rubber coated magnetic sucker is more convenient to be used.

As a professional supplier of magnets & assemblies, Multimagnets offer round and rectangular shape for sales and different colors are available for the rubber coated magnetic bases with handle.

Best used in a shear position, rubber-coated pot magnets have a superior slide resistance over regular magnets due to the increased friction generated between a rubber and smooth steel surface.

Corrosion is the most common reason for a failing magnet. By adding a rubber-coating to a magnet you increase its resistance to corrosion and what’s more they are safe to use on easily marked surfaces without scratching. Typical applications include suspending outdoor cameras, heavy-duty gate and door latches, hanging signage and mounting sensors.

Advantages of MTM's Rubber Coated Magnets For outdoor cameras,Taxi Roof Sign:

1.easy to be produced and assemblied

2.can handle heavy things

3.lower cost and useful for daily life

4.customized designs are acceptable

5.samples are avaible

6.prompt delivery and good after service.

The application of Rubber Coated Magnets :

Thanks to the arrangement of magnets and the rubber coating, this type of magnetic system is ideal for use on surfaces which should not be scratched and / or where movement or slippage of a normal metal pot magnet system is a problem. This makes its use recommended for painted or varnished articles, or for applications where a strong magnetic force is needed, without marking or scratching surfaces.

The rubber protects the magnet in humid conditions where corrosion is likely, and it is widely applied in holding Led Lights and taxi roof signs, vehicle lightings etc.

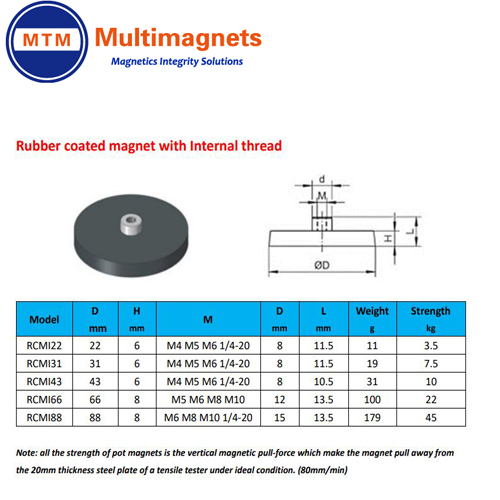

Attached is the standard rubber coated pot magnet, if you need special size or strength, please contact us to customize.