Description

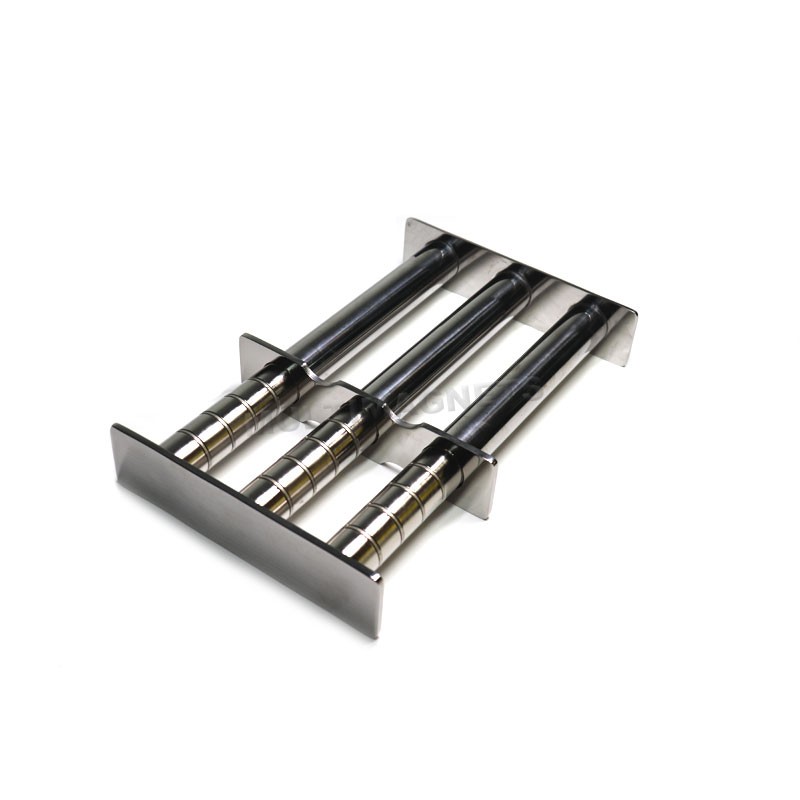

Our Single-Level Magnetic Grate, measuring an optimal 100x300mm, designed for precision magnetic separation in industrial applications. This compact yet powerful solution offers an innovative approach to ensuring product purity and equipment protection, with the added advantage of easy cleaning.

The Single-Level Magnetic Grate is crafted with high-strength rare-earth magnets housed within a sturdy stainless steel frame, guaranteeing efficient removal of ferrous contaminants from dry, granular materials. Its streamlined design allows for seamless integration into various processing lines, providing an unobtrusive yet highly effective solution for maintaining the integrity of your products.

What sets this magnetic grate apart is its user-friendly easy cleaning feature. Engineered with convenience in mind, the grate boasts a quick-release mechanism that facilitates effortless removal for cleaning, eliminating the need for specialized tools or extended downtime. This design ensures that maintenance is a swift and straightforward process, allowing your operations to remain productive and efficient.

Measuring 100x300mm, this single-level magnetic grate offers a versatile solution for industries such as food processing, pharmaceuticals, plastics manufacturing, and more. Its compact dimensions make it suitable for installations where space may be limited, without compromising on magnetic separation performance.

Constructed with durability in mind, the Single-Level Magnetic Grate is resistant to corrosion and wear, ensuring a robust and long-lasting solution for your magnetic separation needs. Trust in the reliability and efficiency of our product to enhance the quality of your processes and protect your valuable equipment.

Upgrade your magnetic separation system with the Single-Level Magnetic Grate, and experience the perfect combination of compact design, powerful performance, and easy cleaning for a seamless integration into your industrial operations.

Our magnetic rods in magnetic grate use TIG welding at the ends (seamless) and then polishing to ensure the good tightness & leakage that is used in liquid environment well.

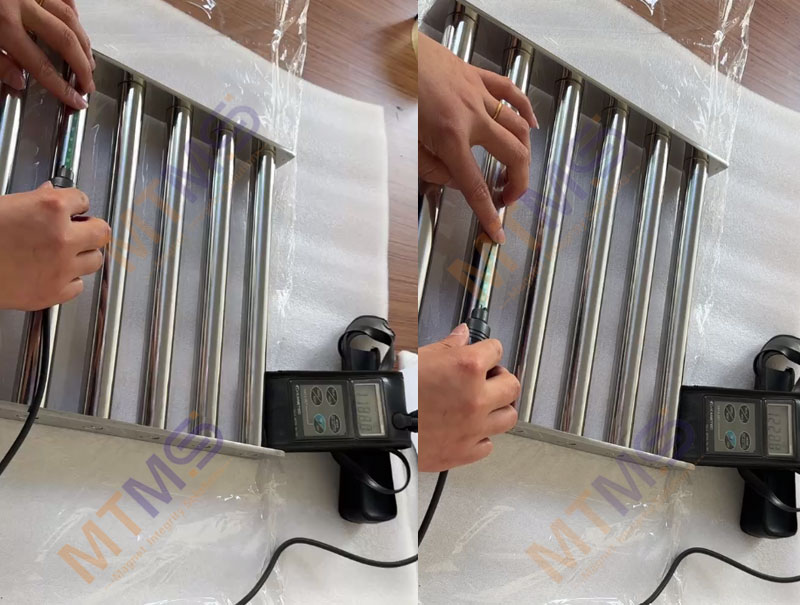

-The maximum magnetic induction intensity can reach 14000Gs for the magnetic bar with the diameter of 25mm.

-The standard working temperature can reach 80ºC and the maximum working temperature can reach 350ºC if need.